High Output machines

Our machines make upgrade work safer and quicker

Network Rail has invested £300m in High Output in the last 12 years – helping to make our High Output fleet the third largest in the world. We maintain and operate our High Output fleet – maintenance is not outsourced.

Why High Output is so important

Ballast cleaning

Over time, ballast wears down and becomes rounded. The pieces of ballast then fit together less easily, reducing the ballast’s effectiveness.

Fine pieces of granite, like sand, are also created by attrition – these are known as ‘fines’. These fines stick together when combined with water in the ballast, making the ballast like a lump of concrete. This hinders track drainage and the flexibility of the ballast to constrain the track as it moves under traffic.

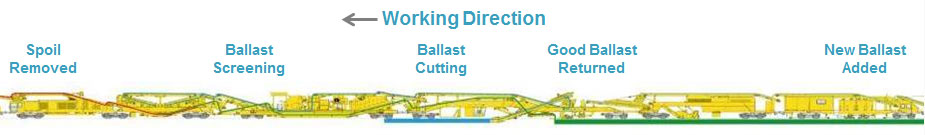

Ballast cleaning removes this worn ballast, screens it and replaces the ‘dirty’ worn ballast with new angular ballast.

With our modern ballast cleaner systems (BCS) there’s a significant reduction in the need for railway workers to be on the track while the work takes place – most operations are controlled from inside the cabs, so this limits exposure to the dangers of diesel fumes, ballast dust and passing trains.

On the newest BCS – the only one that can ballast clean third-rail track – even the wagons are fully automated.

At half-a-mile long, our BCS trains include: locomotives each end (to move the train to and from the work site in traffic up to 60mph); power cars to propel the train while in operation; 22 empty wagons for ballast waste; the ballast cleaner; the tamper/dynamic track stabiliser (DTS) machines (scroll to the end of this page to read more about DTS machines), and 22 wagons full of new ballast. This is a more environmentally friendly alternative to previous ballast cleaners.

How it works

The BCS inserts ballast into the track immediately behind the excavating cutter bar, bringing forward new ballast from its full wagons.

A tamper/DTS, integrated into the machine, improves the track geometry as the whole system progresses along the track, making use of track geometry management systems to install the track position to a high level of precision. The integrated DTS consolidates the track for extra stability.

Any poor quality ballast (spoil) excavated from the track is rejected and fed forwards by conveyors to empty wagons, all contained on the same track.

Because there is no need for wagons on the track alongside the machine, the line adjacent to the BCS can remain open for passenger and freight trains, minimising disruption. The removed spoil is taken back to a High Output Operations Base and then on to specialist facilities to be further processed and recycled as roadstone.

Another advantage of our BCS is that there’s no need to cut rail and remove it for the ballast cleaning process to take place, so our engineers don’t need to dismantle the track and it’s safer. It’s also quicker, and the track can reopen at a line speed of 80mph or more because the rail doesn’t need to be welded (necessary when the rail is cut).

Track renewal

The 800m track renewal system (TRS, pictured above) replaces existing rails and sleepers with high-performing new ones.

The TRS works in a similar conveyored system to the ballast cleaner. The front part runs on the old rails, while the rear runs on the new rail that the system has installed, so any lines adjacent to the one the TRS is working on can remain open to passing trains.

Sleepers can’t be carried to and from the work site on the TRS in the normal orientation (across the track), so a crane fitted with a turntable rotates them through 90 degrees while moving them from the delivery wagon to the installation mechanisms, and at the same time loads the old sleepers on to the empty wagon.

Although it has similar tamping/consolidation machines to those deployed with the BCS, working in harmony, restoring line speed after work is more complex as the rails have to be welded before they are stressed (stretched with hydraulic tensors) – the result of having to install new rails that are delivered in lengths no greater than 216 metres.

An undercutting machine follows the TRS after the new track has been installed, to ensure the track is lowered below its proposed design position. Then the tamper/DTS carries out the final precision placement of the track by applying lift and small horizontal track position adjustments – with the DTS unit consolidating the track by applying a vibrating roller to remove the gaps between the ballast.

Dynamic Track Stabilisation

High Output tamping machines are slightly different from those typically used for track maintenance.

With ‘standard’ tampers there’s generally a line speed restriction of around 50mph for a week after track renewal, to allow the ballast to settle. When Dynamic Track Stabilisation (DTS) technology is available on a tamper, it exerts a vertical downward force on the track, while also vibrating it side to side. This helps to settle the ballast and increases track stability.

The impact of a DTS machine is equivalent to up to a week’s worth of train tonnage. The track settles in a controlled manner during the renewal work and won’t settle further as trains pass over it later. The result is that trains can run on the track at high speeds (80-125mph) straight after renewal work – called a high-speed handback.

DTS machines have typically been used with High Output tampers on plain line sections of track to achieve high-speed handbacks.

Electrification

Our High Output Plant System (HOPS) is used for electrification of the Great Western Mainline.

Awards

Our High Output track renewals team was recently awarded the British Council Sword of Honour, and the team’s work contributed to Network Rail (High Output) being voted Recycler of the Year 2016 – Find out more about our rewards.